February 2024 | 3087 words | 11-minute read

A 75,000sq m expanse. 1,75,000cu m of concrete, 60,000m of piping, 80,000sq m of stonework, 90,000sq m of ducting, 27,000MT of reinforcement, 1,350km of cable and wiring (longer than the distance between Mumbai and Chennai).

All brought together by a 60,000-strong workforce, over 29 lakh labour days, and Tata Projects to build India’s new Parliament building.

“The fact that Tata Projects got the opportunity to build this is something that associates not only Tata Projects but also, we as Tata as a whole, our name, with writing the history about this,” says Vinayak Deshpande, the former Managing Director of Tata Projects, who helmed this project.

Tata Projects, bolstered by One Tata synergies, constructed this iconic building in record time for its inauguration in 2023.

A landmark project

The significance of the new Parliament building cannot be understated. It is the first Parliament House to be built by India after Independence, and a core part of the ambitious makeover of Central Vista, which includes Kartavya Path (formerly known as Rajpath), Common Central Secretariat, Executive Enclave, the National Museum and the National Archives. It will be witness to history being enacted in its chambers, where peoples’ representatives from all walks of life will debate over legislative minutiae and make decisions that will change the destiny of a country.

“The fact that Tata Projects got the opportunity to build this is something that associates not only Tata Projects but also, we as Tata as a whole, our name, with writing the history about this," says Vinayak Deshpande

That the building will be iconographic and will have its own historicity is a given.

While the architectural design was entrusted to the Ahmedabad-based firm HCP Design, Planning and Management, Tata Projects won the bid for its construction, with its responsibilities ranging from advisory on buildability, project management, mechanical, electrical and plumbing (MEP), information and communication technology (ICT), multimedia and voting systems technology, to a total handover, complete in all respects.

The three-point brief

The brief for the new Parliament from the commissioning authority, the Central Public Works Department (CPWD), was crystal clear. The building was to be iconic and, in the years to come, be a symbol of the nation’s government, emphasising its stability and progress. The quality of the structure, therefore, would have to live up to the highest standards possible, architecturally and structurally.

The second ask was related to the construction itself. Being, as it was, in the heart of the capital city, plot no 118 of Parliament House Estate — also called West Block — was less than 100m from the old Parliament building and surrounded by many heritage structures. Sessions would be underway, and some of these buildings housed important ministries with a working population in the thousands. Tata Projects would, therefore, have to execute the project in stealth fashion, without any compromise on safety, noise and particle pollution, or environmental standards during the construction phase.

But the primary and the most challenging part of the brief was the deadline — the whole project, from start to finish, had to be completed within 26 months. The countdown began on December 10, 2020, the day the bhoomi pujan and foundation stone laying ceremony of the new Parliament building took place.

The foundation of a structural marvel

By any yardstick, the complexities of the construction were challenging.

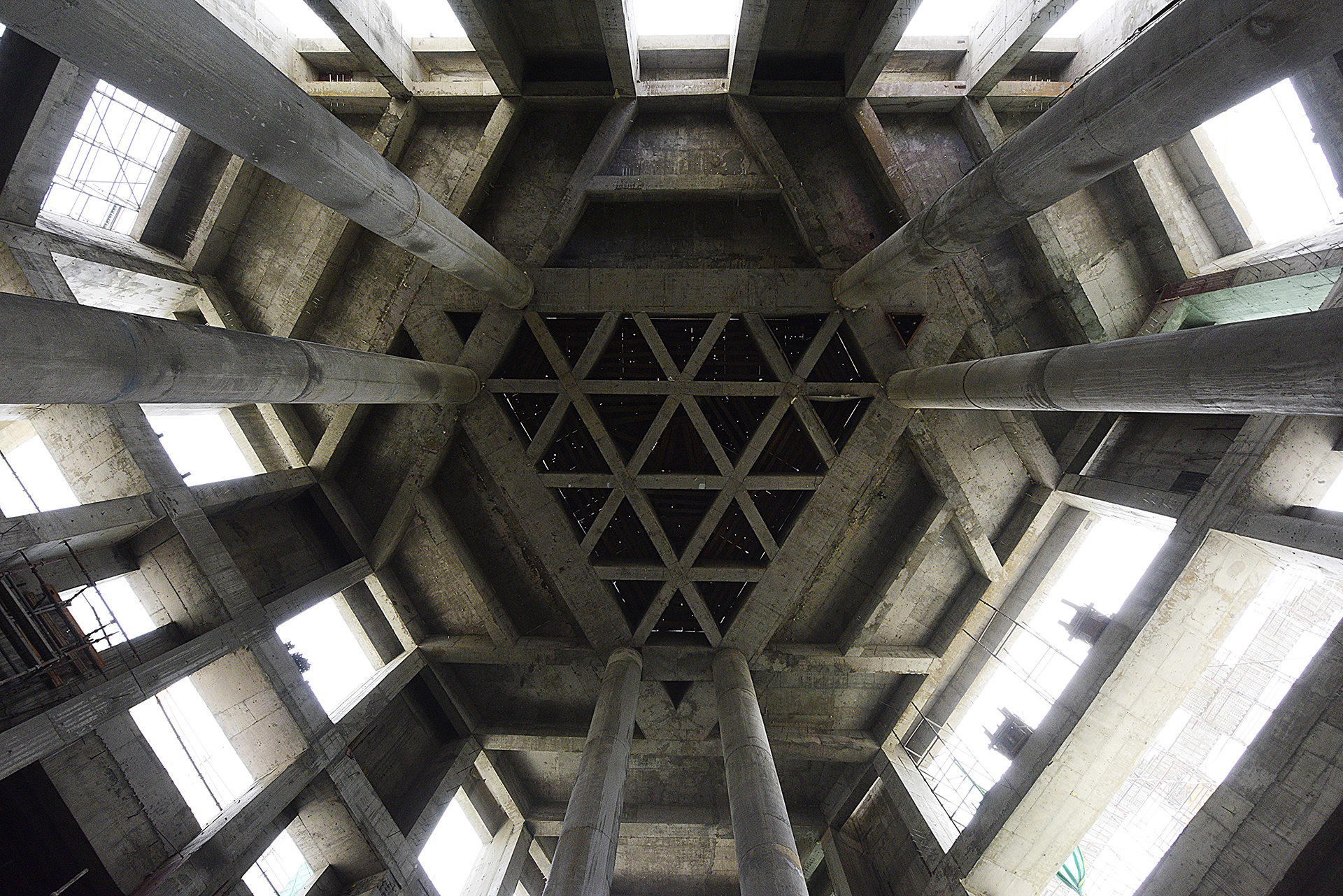

Besides the constraints placed by the location of the plot — amidst heritage structures, abundant greenery, a functioning Parliament House with legislators, other VIPs and dignitaries and hundreds of government officials — the building had to adhere to the critical structural requirements that would make it failure-proof, secure, and stand strong for the foreseeable future. In addition, the building’s architecture called for the use of heavy stone cladding, high ceilings on slender pillars, and many finer and detailed aesthetic features, all of which required heavy-duty reinforced cement concrete (RCC) construction.

Besides the constraints placed by the location of the plot — amidst heritage structures, abundant greenery, a functioning Parliament House with legislators, other VIPs and dignitaries and hundreds of government officials — the building had to adhere to the critical structural requirements that would make it failure-proof, secure, and stand strong for the foreseeable future. In addition, the building’s architecture called for the use of heavy stone cladding, high ceilings on slender pillars, and many finer and detailed aesthetic features, all of which required heavy-duty reinforced cement concrete (RCC) construction.

The national capital territory (Delhi NCR) is prone to tremors and located in seismic zone IV, which stands for ‘severe intensity’. However, to ensure that the building could withstand much more, engineers went one step further — they adhered to structural standards required for a seismic zone V building. This meant, among other things, that the concrete had to be of a mix design of M50 and M60, considered very high-grade, and the diameter of the steel used for reinforcement had to be up to 40mm. The volumes of concrete required were enormous as well — around 1,75,000cu m needed to be produced. All this — the foundation and RCC work — would have to be completed within the first 12 months of the project to achieve the overall completion date.

The constraints of the plot, the entirety of which was occupied by the building, and the location, made it impossible for much of the heavy work to be done in situ. The bending and cutting of the steel reinforcements, mixing of concrete and production of prefabricated sections were done at a site in Delhi’s Kirti Nagar, around 10km away from West Block. The sheer volume of concrete for the 12 months translated to 14,000cu m a month on average, sometimes peaking to 18,000cu m a month, which had to be produced, transported and poured daily.

This called for extreme levels of precision, detailed planning and flawless execution. Says Mr Deshpande, “The volumes were very challenging. But our engineers were very methodical about it: they had very precise pour sequences of concrete across zones. We planned meticulously around steel reinforcement and concreting. The team never, ever missed the target at any point.”

A beauty emerges

Designed by HCP, with the active involvement of the Prime Minister’s Office and relevant ministries, the new Parliament building displays a high level of aesthetics through the art, culture and architecture of different parts of India. Within 12 months, the RCC structure was ready for these finer aspects of the building to be laid out. The next 12 months would be critical — it would not only ask the best of the workmen, engineers, managers and architects on the site, but also of various craftsmen, artists and weavers from around the country.

The exterior of the building, which is a combination of red and white sandstone — a feature of Indian heritage architecture — covers around 45,000sq m. The sandstone is around 40-225mm thick, with each precise cut weighing on average 90kg, with some stones weighing as much as 800kg. The stone had to be cut at quarries in Rajasthan, transported to the site and tightly bolted on the wall surface of the building — the requirements for seismic zone V did not leave any margin for error. The team targeted seven months for this activity, to accommodate time for further finishing, estimating a coverage of 6,000-7,000sq m a month. During the first month, it was felt that the pace was not possible to achieve — where 200-250sq m a day was needed, less than 10sq m was being built. At this point, it was feared that deadlines would be missed.

But real leadership shines through at such moments. “Our civil engineers did a great job,” says Mr Deshpande. “When I said that we need to move to 200 to 250sq m a day, and need to crank this up quickly, they started fixing the stone themselves with the workmen so that they could understand the issues.”

After about 10 days of activity, the engineers figured out where the issues lay, and redesigned the entire process. “They solved this in a Six Sigma manner, and the productivity jumped from 4 to 40 to 100 to 200sq m,” he adds. “The first month was tough, but we were doing 220-240sq m in the second month itself.”

Another structural challenge that called for engineering ingenuity were the large chambers of the Lok Sabha, the Rajya Sabha and the Constitution Hall that occupy the full height of the four floors of the building. Adding to this were the artistic ceilings, a peacock feather theme for the Lok Sabha and a lotus motif for the Rajya Sabha, which were imagined as unsupported roofs. Each ceiling spans 47m and had to be hung with a steel structure from the top concrete slab. Each of these steel structures alone weighs about 220tonnes — equivalent to the weight of five jet aircraft.

To round it off, only the final erection could be done in situ; everything else needed to be done offsite. Mr Deshpande recalls how Tata Projects took this on: “A fully digital duplicate was created, and an entire 3D analysis was done. With the modelling, we designed each piece, which was then fabricated, brought to site, and bolted. Like you would build a Lego or Meccano set.” The use of high-end 3D modelling, precise computer numerical controlled (CNC) fabrication, meticulous planning and painful attention to detail by Tata Projects’ engineers and site workmen accomplished in a month what otherwise would have taken several more through conventional methods.

This alacrity was on display during every stage of the project, notably those that involved sourcing critical elements from various parts of the country. This included the production and installation of the national emblem, the Ashoka stambh, atop the building. The bronze emblem weighs close to 10tonnes and has a 6.5-tonne steel support structure. The sculpture was smelted in Jaipur, transported in sections to the site and gas-welded in place on the roof. To ensure that the logistics were in place and delivery was on time, Tata Projects’ engineers camped on site, participating throughout the process. Says Mr Deshpande, “Our engineers walked the path (of the vendors). We had our people camping near the Rajasthan (sandstone) quarries, sourcing the stone themselves. Our engineers were camping at the sculptor’s site in Jaipur, Rajasthan; the furniture workshops in Navi Mumbai, Maharashtra; and the carpet weavers in the Mirzapur area of Uttar Pradesh.”

The technological backbone

The new Parliament House is built to stay in step with the pace of the world outside and is powered by state-of-the-art technology. The primary focus is to provide legislators with a seamless, user-friendly, secure and efficient way of conducting house affairs, both at the individual and collective level. Additionally, security, access control and a fail-proof IT infrastructure were also critical given the primacy of the Parliament in the country’s functioning.

Tata Projects had the responsibility of executing the technology infrastructure as well.

A key feature of the new building is the ‘paperless’ mode of legislation, where every seat has a tablet with multi-language capability, representing the linguistic diversity of India, intranet and internet access, access to digital libraries and the national internet backbone (NIC), in addition to the critical voting systems. The voting systems are designed in such a way that legislation is passed with transparency, with each vote being unique — a legislator will not be able to cast their vote from more than one tablet. Instant verbal and written translation enable seamless communication, so that legislators can always use a language they are comfortable with.

The audio-visual footprint of the building is also high, with large-format screens and sound systems available at both the halls, in the conference and committee rooms, as well as the members’ chambers and visitor lounges. The entire ICT stack used in the building is highly secure and responsive, to ensure zero breach and deter cyberattacks.

Technology plays a significant role in physical security as well — the entry and exit systems, visitor management systems and wide coverage by CCTV ensure that the premises are monitored 24/7 and are highly secure.

The Tata way

Perhaps the toughest — and the most inspiring — part of the story of the construction of the new Parliament building was the impact of the Covid-19 pandemic that was sweeping through the world as the project kicked off. At the time of the bhoomi pujan in December 2020, the first wave had already swept through the country, and lockdown restrictions were gradually being lifted, while precautions such as masks, hand hygiene and social distancing were still in place. Business cycles had been disrupted, and several vendors had significant challenges with their own workforce and suppliers.

Mr Deshpande recalls how Tata Sons Chairman N Chandrasekaran’s clear direction helped them overcome these hurdles. “Everyone was going through a difficult time. Our vendors required cash flow support. We had very clear direction from our leadership that we must make sure that we do not make anyone suffer for cash flow, and this helped a great deal.”

When the Delta wave struck in 2021, the Tata group’s Covid-19 task force stepped in to ensure adequate precautions and protection — ensuring oxygen support, medical care and hospital accommodation where necessary. Says Mr Deshpande, “The task force for the north zone took care of every individual, irrespective of which company they were part of. It wasn’t just Tata Projects taking care of its employees. It was a group-wide effort with personnel from many Tata companies who were taking care of all individuals on the site. The situation outside was serious, but we worked as one united force all through the Covid period.”

"Our Chairman Mr Chandrasekaran would visit once in two months and meet all the workmen, our engineers, our people, and he made every material support that was required possible," says Mr Deshpande

A bio-bubble for around 2,500 workmen was created close to the site. The work continued without a pause, at times. The energy and the ‘mission-mode’ drive by all hands, recalls Mr Deshpande, created a sense of camaraderie that united everyone — from workmen to supervisors to engineers and the leadership, including the chairman, Mr Chandrasekaran, who visited the site every two months. Says Mr Deshpande, “The entire team worked almost as if they were fighting a war. We were so united, the workmen, our engineers, our supervisors, and others. There was never a hierarchy; we worked as a unified team.” And delivered on time.

National duty

The company believes that the on-time execution of this project has effectively demonstrated its civil engineering and mechanical, electrical and plumbing (MEP) capabilities. This experience will hold it in good stead for other large building projects, like the Noida Airport, which requires similar skills — precise shell and core construction, electromechanical systems, and high grade of finishes. For a company that was largely focused on industrial infrastructure, the new Parliament building gives it qualification credits of the highest order for the entire urban infrastructure market, be it in India or elsewhere. “This is a great track record for Tata Projects, that we created such a complex structure — very high on architectural finishes, very high on technology integration, very high on sustainability, safety, security and many such aspects — in the record time of 26 months,” says Mr Deshpande. “I cannot believe we did this in 26 months. It happened only because everyone, right from the worker to the engineer, to the supervisor, to a person like me, did this as a national duty.”

He adds, “And there were two great driving forces — the prime minister himself and our group chairman. Prime Minister Narendra Modi visited the project multiple times, and each time he would come, he would encourage the workforce. Our Chairman Mr Chandrasekaran would visit once in two months and meet all the workmen, our engineers, our people, and he made every material support that was required possible. If we didn’t have this kind of support, it would have been difficult to make this happen..”

Leveraging One Tata strengths

- Voltas: The company executed the high-end, heavy-duty heating, ventilation and air conditioning requirements of the new Parliament building. “Voltas played a very important role,” says Mr Deshpande. “From the chiller plant room and the air handling unit to the ducting, and the whole air conditioning and ventilation, they did a fantastic job.”

- Tata Steel: All the steel for the building is supplied by Tata Steel. “There’s a great coincidence here,” says Mr Deshpande. “When we went to see the old Parliament building and saw the trusses at the top, which support the dome structure of the Lok Sabha and Rajya Sabha, we found they were made of Tata Steel. The building was built in 1921, so the stamp says TISCO, Tata Iron and Steel Company, as the company was known then.”

- Tata Consultancy Services: The new Parliament building is paperless, which entailed software-related expertise to integrate the new hardware with the existing local and parliamentary databases. “A lot of the integration is complex and intricate. This is where TCS stepped in and provided the backup support and understanding of software integration nuances that we needed to source the equipment and execute this part,” says Mr Deshpande. When the project faced challenges in the acquisition of high-end electronics during the pandemic, TCS was once again there to help, says Mr Deshpande. “During Covid, electronic supply chains were disrupted globally. We had to get priorities negotiated with suppliers, and TCS connects were really helpful.”

- Tata Consulting Engineers: The company provided design engineering services. TCE worked with HCP, the main architecture consultant for the building, on various utility systems and external infrastructure, from conceptualisation to detailed engineering and need-based quality inspection at the site.

- Titan: All the 191 clocks that keep time for the Parliament are electronically synchronised with the central server system and are supplied by Titan.

- Tata Motors and Tata Power: A lesser-known fact is that both these companies brought their expertise in building green habitats inside and outside their campuses to this project. They deputed their staff to help the Parliament staff with landscaping, gardening, and other horticultural developments for the building.

- Monali Sarkar and Haroon Bijli